High-Value Software Solutions to Costly Industrial Corrosion

Recommended Corrosion Prediction Software and Corrosion Modeling Software

for Corrosion Risk Assessment and Corrosion Life Prediction

• Corrosion Prediction Software Selection by Industry

Why WebCorr |

Performance Guarantee |

Unparalleled Functionality |

Unmatched Usability |

Any Device Any OS |

Free Training & Support |

CorrCompass

Protecting People,

Assets, and the

Environment from the Harmful Effect of Corrosion with

Predictive Modeling Software

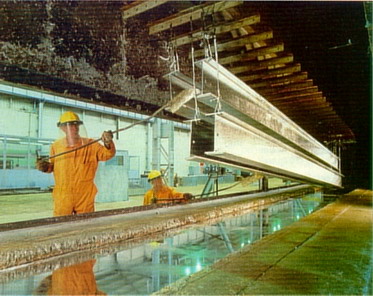

Corrosion is a disease to materials just like a disease to human beings. Corrosion affects the material's properties and weakens the mechanical integrity of engineering systems. It poses a major risk to

the environment and many industrial facilities and structures such as

oil and gas pipelines, storage tanks, boilers, heat exchangers, and other equipment and systems. To estimate the design life or residual life of an industrial component, corrosion rate data for a given material-environment system must be known. WebCorr's high-value

corrosion prediction software and

corrosion modeling software can provide essential corrosion rate data to the design team, and the operation, inspection, and maintenance personnel, making possible a more realistic estimation of the design life or residual life of a component or asset.

WebCorr has developed 47 integrated

predictive software programs for corrosion prediction and corrosion modeling, cementing a CorrCompass-based ecosystem

encompassing different types of corrosion in every industry and service environment. Click the corrosion software title for details on each software and the relevant application examples. If you cannot find the

corrosion prediction software of your interest, do let us know through the

Contact Us link and we will work with you to develop a customized software for you.

Alternatively, we can run the appropriate corrosion prediction software

for you as a service using the data you provide to us.

|

Corrosion Prediction Software for the Oil and Gas Industry

|

CO2Compass: Modeling and Prediction of Corrosion by Carbon Dioxide (CO2), Hydrogen Sulfide (H2S), Acetic Acid (HAc), Elemental Sulfur (S), and Mercury (Hg) in Oil and Gas Pipelines and Production Tubing.

ISO15156-Compass: Modeling and Prediction of in-situ pH, Region of Environmental Severity, and Susceptibility to Sulfide Stress Cracking (SSC) of Carbon and Low Alloy Steels

MIC-Compass: Modeling and Prediction of Microbiologically Influenced Corrosion in Oil and Gas Pipelines

OCTG-Compass: Corrosion Prediction and CRA Materials Selection Guide for Oil and Gas Production Systems

EN-Compass: Modeling and Prediction of the Corrosion Resistant Properties of Electroless Nickel Coatings

PCW-Compass: Corrosion Prediction and Modeling in Process Cooling Water Systems

CP-Compass: Cathodic Protection Design Calculations, Verification, Assessment and Solutions.

CRA-Compass: Corrosion Modeling and Corrosion Prediction for Corrosion Resistant Alloys - the Threshold Temperature and Chloride Concentration for Pitting, Crevice Corrosion, and Stress Corrosion Cracking (SCC).

GC-Compass: Galvanic Corrosion Prediction and Materials Compatibility Assessment

SC-Compass: Stray Current Corrosion and AC Corrosion - Identification, Assessment and Prediction

Atmosphere-Compass: Prediction and Modeling of Atmospheric Corrosion of Metals and Alloys

Soil-Compass: Soil Corrosion Prediction and Modeling for Metals and Alloys

Seawater-Compass: Seawater Corrosion Prediction for Metals and Alloys

SPE-Compass: Solid Particle Erosion Modeling and Prediction

Concrete-Compass: Concrete Corrosion Prediction and Modeling

ACE - Apps for Corrosion Engineers: A Collection of Essential Corrosion Software Applications for Corrosion Engineers, Corrosion Researchers, and Corrosion Technicians in Laboratories and in Fields

WebCorr Corrosion Rate Units Converter: Converting Between All Corrosion Rate Units for All Metals and Alloys

|

|

Corrosion Prediction Software for the Pipeline Industry

|

PipelineCompass: Pipeline Corrosion Modeling, Prediction, Assessment and Solutions

MIC-Compass: Modeling and Prediction of Microbiologically Influenced Corrosion in Oil and Gas Pipelines

CP-Compass: Cathodic Protection Design Calculations, Verification, Assessment and Solutions

CO2Compass: Modeling and Prediction of Corrosion by Carbon Dioxide (CO2), Hydrogen Sulfide (H2S), Acetic Acid (HAc), Elemental Sulfur (S), and Mercury (Hg) in Oil and Gas Pipelines and Production Tubing

ACMF-Compass: Modeling and Prediction of the Effects of AC and Magnetic Field on Metal Corrosion

PCW-Compass: Corrosion Prediction and Modeling in Process Cooling Water Systems

SC-Compass: Stray Current Corrosion and AC Corrosion - Identification, Assessment and Prediction

Soil-Compass: Soil Corrosion Prediction and Modeling for Metals and Alloys

Seawater-Compass: Seawater Corrosion Prediction for Metals and Alloys

Concrete-Compass: Concrete Corrosion Prediction and Modeling

CRA-Compass: Corrosion Modeling and Corrosion Prediction for Corrosion Resistant Alloys - the Threshold Temperature and Chloride Concentration for Pitting, Crevice Corrosion, and Stress Corrosion Cracking (SCC)

CUI-Compass: Prediction and Risk Assessment of Corrosion Under Insulation and Fireproofing

EVS-Compass: Extreme Value Statistics in Corrosion Modeling and Corrosion Life Prediction of Structures and Plant Assets

ACE - Apps for Corrosion Engineers: A Collection of Essential Corrosion Software Applications for Corrosion Engineers, Corrosion Researchers, and Corrosion Technicians in Laboratories and in Fields

WebCorr Corrosion Rate Units Converter: Converting Between All Corrosion Rate Units for All Metals and Alloys

|

|

Corrosion Prediction Software for the Oil Refining, Petrochemical, Chemical Processing, Pharmaceutical, Pulp & Paper, Energy & Power Industries

|

H2Compass: Modeling and Prediction of Low Temperature Hydrogen Damages (Hydrogen Blistering, Hydrogen-Induced Cracking, Hydrogen Embrittlement) and High Temperature Hydrogen Attack (HTHA)

Cl2Compass: Modeling and Prediction of Corrosion by Dry Chlorine Gas

CSR-Compass: Modeling and Remaining Life Prediction of Creep and Stress Rupture of Boiler and Heater Tubes

NAC-Compass: Modeling and Prediction of High Temperature Naphthenic Acid Corrosion

S-Compass: Modeling and Prediction of High Temperature Sulfidation/Sulfidic Corrosion/H2-H2S Corrosion and Low Temperature Elemental Sulfur Corrosion

O2Compass: Modeling and Prediction of High Temperature Oxidation

NH3-Compass: Modeling and Prediction of Corrosion in Ammonia Production, Storage, and Transport

CCC-Compass: Modeling and Prediction of Caustic Corrosion and Caustic Stress Corrosion Cracking

MSC-Compass: Modeling and Prediction of Molten Salt Corrosion in TES and MSR Applications

FuelAsh-Compass: Fuel Ash Corrosion Modeling and Life Prediction of Boiler and Heater Tubes

ABC-Compass: Ammonium Bisulfide Corrosion Modeling and Life Prediction

MIC-Compass: Modeling and Prediction of Microbiologically Influenced Corrosion in Oil and Gas Pipelines

FAC-Compass: Erosion Corrosion and Flow - Accelerated Corrosion Modeling, Life Prediction and Materials Selection in Water-Steam Systems

PCW-Compass: Corrosion Prediction and Modeling in Process Cooling Water Systems

ACMF-Compass: Modeling and Prediction of the Effects of AC and Magnetic Field on Metal Corrosion

CRA-Compass: Corrosion Modeling and Corrosion Prediction for Corrosion Resistant Alloys - the Threshold Temperature and Chloride Concentration for Pitting, Crevice Corrosion, and Stress Corrosion Cracking (SCC)

CUI-Compass: Prediction and Risk Assessment of Corrosion Under Insulation and Fireproofing

Dew-Point-Compass: Prediction of Dew Point Temperatures of Flue Gases and the Risk of Dew Point Corrosion

H2SO4-Compass: Corrosion Prediction and Materials Selection Guide for H2SO4 Services

HBr-Compass: Corrosion Prediction and Materials Selection Guide for Hydrobromic Acid (HBr) Services

HCl-Compass: Corrosion Prediction and Materials Selection Guide for HCl Services

HF-Compass: Corrosion Prediction and Materials Selection Guide for HF Services

GC-Compass: Galvanic Corrosion Prediction and Materials Compatibility Assessment

CIPAL-Compass: Copper-Induced Pitting in Aluminium Alloys - Modeling, Life Prediction and Process Control

CP-Compass: Cathodic Protection Design Calculations, Verification, Assessment and Solutions

SC-Compass: Stray Current Corrosion and AC Corrosion - Identification, Assessment and Prediction

Soil-Compass: Soil Corrosion Prediction and Modeling for Metals and Alloys

Seawater-Compass: Seawater Corrosion Prediction for Metals and Alloys

Concrete-Compass: Concrete Corrosion Prediction and Modeling

Atmosphere-Compass: Prediction and Modeling of Atmospheric Corrosion of Metals and Alloys

VPC-Compass: Prediction and Modeling of Internal Corrosion in Vapor Phase in Closed Systems

EVS-Compass: Extreme Value Statistics in Corrosion Modeling and Corrosion Life Prediction of Structures and Plant Assets

ACE - Apps for Corrosion Engineers: A Collection of Essential Corrosion Software Applications for Corrosion Engineers, Corrosion Researchers, and Corrosion Technicians in Laboratories and in Fields

WebCorr Corrosion Rate Units Converter: Converting Between All Corrosion Rate Units for All Metals and Alloys

|

|

Corrosion Prediction Software for the Marine and Offshore Industry

|

Seawater-Compass: Seawater Corrosion Prediction for Metals and Alloys

Atmosphere-Compass: Prediction and Modeling of Atmospheric Corrosion of Metals and Alloys

ISO15156-Compass: Modeling and Prediction of in-situ pH, Region of Environmental Severity, and Susceptibility to Sulfide Stress Cracking (SSC) of Carbon and Low Alloy Steels

MIC-Compass: Modeling and Prediction of Microbiologically Influenced Corrosion in Oil and Gas Pipelines

CRA-Compass: Corrosion Modeling and Corrosion Prediction for Corrosion Resistant Alloys - the Threshold Temperature and Chloride Concentration for Pitting, Crevice Corrosion, and Stress Corrosion Cracking (SCC)

GC-Compass: Galvanic Corrosion Prediction and Materials Compatibility Assessment

CUI-Compass: Prediction and Risk Assessment of Corrosion Under Insulation and Fireproofing

PipelineCompass: Pipeline Corrosion Modeling, Prediction, Assessment and Solutions

CP-Compass: Cathodic Protection Design Calculations, Verification, Assessment and Solutions

Soil-Compass: Soil Corrosion Prediction and Modeling for Metals and Alloys

Concrete-Compass: Concrete Corrosion Prediction and Modeling

EVS-Compass: Extreme Value Statistics in Corrosion Modeling and Corrosion Life Prediction of Structures and Plant Assets

ACE - Apps for Corrosion Engineers: A Collection of Essential Corrosion Software Applications for Corrosion Engineers, Corrosion Researchers, and Corrosion Technicians in Laboratories and in Fields

WebCorr Corrosion Rate Units Converter: Converting Between All Corrosion Rate Units for All Metals and Alloys

|

|

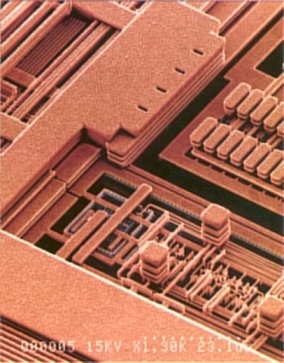

Corrosion Prediction Software for the Microelectronics and Semiconductor Manufacturing Industry

|

VPC-Compass-SE: Prediction and Modeling of Corrosion in Microelectronic Packages

CIPAL-Compass: Copper-Induced Pitting in Aluminium Alloys - Modeling, Life Prediction and Process Control

PCW-Compass: Corrosion Prediction and Modeling in Process Cooling Water Systems

GC-Compass: Galvanic Corrosion Prediction and Materials Compatibility Assessment

ACMF-Compass: Modeling and Prediction of the Effects of AC and Magnetic Field on Metal Corrosion

Atmosphere-Compass: Prediction and Modeling of Atmospheric Corrosion of Metals and Alloys

O2Compass: Modeling and Prediction of High Temperature Oxidation

ACE - Apps for Corrosion Engineers: A Collection of Essential Corrosion Software Applications for Corrosion Engineers, Corrosion Researchers, and Corrosion Technicians in Laboratories and in Fields

WebCorr Corrosion Rate Units Converter: Converting Between All Corrosion Rate Units for All Metals and Alloys

|

|

Corrosion Prediction Software for the Desalination, Water and Waste Water Industries

|

Seawater-Compass: Seawater Corrosion Prediction for Metals and Alloys

H2O-Compass: Modeling and Prediction of Water Corrosivity and Scaling Tendency

PipelineCompass: Pipeline Corrosion Modeling, Prediction, Assessment and Solutions

PCW-Compass: Corrosion Prediction and Modeling in Process Cooling Water Systems

DWD-Compass: Modeling and Life Prediction of Corrosion in Drinking Water Distribution Systems

CRA-Compass: Corrosion Modeling and Corrosion Prediction for Corrosion Resistant Alloys - the Threshold Temperature and Chloride Concentration for Pitting, Crevice Corrosion, and Stress Corrosion Cracking (SCC)

GC-Compass: Galvanic Corrosion Prediction and Materials Compatibility Assessment

CP-Compass: Cathodic Protection Design Calculations, Verification, Assessment and Solutions

Soil-Compass: Soil Corrosion Prediction and Modeling for Metals and Alloys

Concrete-Compass: Concrete Corrosion Prediction and Modeling

CUI-Compass: Prediction and Risk Assessment of Corrosion Under Insulation and Fireproofing

Dew-Point-Compass: Prediction of Dew Point Temperatures of Flue Gases and the Risk of Dew Point Corrosion

Atmosphere-Compass: Prediction and Modeling of Atmospheric Corrosion of Metals and Alloys

CIPAL-Compass: Copper-Induced Pitting in Aluminium Alloys - Modeling, Life Prediction and Process Control

SC-Compass: Stray Current Corrosion and AC Corrosion - Identification, Assessment and Prediction

WebCorr Corrosion Rate Units Converter: Converting Between All Corrosion Rate Units for All Metals and Alloys

|

|

Corrosion Prediction Software for the Public Transportation Industry

|

SC-Compass: Stray Current Corrosion and AC Corrosion - Identification, Assessment and Prediction

Concrete-Compass: Concrete Corrosion Prediction and Modeling

Soil-Compass: Soil Corrosion Prediction and Modeling for Metals and Alloys

Seawater-Compass: Seawater Corrosion Prediction for Metals and Alloys

Atmosphere-Compass: Prediction and Modeling of Atmospheric Corrosion of Metals and Alloys

GC-Compass: Galvanic Corrosion Prediction and Materials Compatibility Assessment

PCW-Compass: Corrosion Prediction and Modeling in Process Cooling Water Systems

CRA-Compass: Corrosion Modeling and Corrosion Prediction for Corrosion Resistant Alloys - the Threshold Temperature and Chloride Concentration for Pitting, Crevice Corrosion, and Stress Corrosion Cracking (SCC)

CP-Compass: Cathodic Protection Design Calculations, Verification, Assessment and Solutions

EVS-Compass: Extreme Value Statistics in Corrosion Modeling and Corrosion Life Prediction of Structures and Plant Assets

VPC-Compass: Prediction and Modeling of Internal Corrosion in Vapor Phase in Closed Systems

WebCorr Corrosion Rate Units Converter: Converting Between All Corrosion Rate Units for All Metals and Alloys

|

|

Corrosion Prediction Software for the Automotive and Aerospace Industries

|

GC-Compass: Galvanic Corrosion Prediction and Materials Compatibility Assessment

CRA-Compass: Corrosion Modeling and Corrosion Prediction for Corrosion Resistant Alloys - the Threshold Temperature and Chloride Concentration for Pitting, Crevice Corrosion, and Stress Corrosion

Cracking (SCC)

H2Compass: Modeling and Prediction of Low Temperature Hydrogen Damages

(Hydrogen Blistering, Hydrogen-Induced Cracking, Hydrogen Embrittlement) and High Temperature Hydrogen Attack (HTHA)

PCW-Compass: Corrosion Prediction and Modeling in Process Cooling Water Systems

VPC-Compass: Prediction and Modeling of Internal Corrosion in Vapor Phase in Closed Systems

Atmosphere-Compass: Prediction and Modeling of Atmospheric Corrosion of Metals and Alloys

O2Compass: Modeling and Prediction of High Temperature Oxidation

CSR-Compass: Modeling and Remaining Life Prediction of Creep and Stress Rupture of High Temperature Components

WebCorr Corrosion Rate Units Converter: Converting Between All Corrosion Rate Units for All Metals and Alloys

|

|

Corrosion Prediction Software for the Defense and Military Industry

|

GC-Compass: Galvanic Corrosion Prediction and Materials Compatibility Assessment

Atmosphere-Compass: Prediction and Modeling of Atmospheric Corrosion of Metals and Alloys

Seawater-Compass: Seawater Corrosion Prediction for Metals and Alloys

CRA-Compass: Corrosion Modeling and Corrosion Prediction for Corrosion Resistant Alloys - the Threshold Temperature and Chloride Concentration for Pitting, Crevice Corrosion, and Stress Corrosion Cracking (SCC)

PCW-Compass: Corrosion Prediction and Modeling in Process Cooling Water Systems

CP-Compass: Cathodic Protection Design Calculations, Verification, Assessment and Solutions

Soil-Compass: Soil Corrosion Prediction and Modeling for Metals and Alloys

Concrete-Compass: Concrete Corrosion Prediction and Modeling

PipelineCompass: Pipeline Corrosion Modeling, Prediction, Assessment and Solutions

FAC-Compass: Erosion Corrosion and Flow - Accelerated Corrosion Modeling, Life Prediction and Materials Selection in Water-Steam Systems

VPC-Compass: Prediction and Modeling of Internal Corrosion in Vapor Phase in Closed Systems

WebCorr Corrosion Rate Units Converter: Converting Between All Corrosion Rate Units for All Metals and Alloys

|

|

Corrosion Prediction Software for the

Nuclear Waste Transport, Storage,

and Disposal

|

Atmosphere-Compass: Prediction and Modeling of Atmospheric Corrosion of Metals and Alloys

Soil-Compass: Soil Corrosion Prediction and Modeling for Metals and Alloys

Concrete-Compass: Concrete Corrosion Prediction and Modeling

CP-Compass-Concrete: Design Calculations for Cathodic Protection of Reinforced Concrete Structures

GC-Compass: Galvanic Corrosion Prediction and Materials Compatibility Assessment

CRA-Compass: Corrosion Modeling and Corrosion Prediction for Corrosion Resistant Alloys - the Threshold Temperature and Chloride Concentration for Pitting, Crevice Corrosion, and Stress Corrosion Cracking (SCC)

SC-Compass: Stray Current Corrosion and AC Corrosion - Identification, Assessment and Prediction

ACE - Apps for Corrosion Engineers: A Collection of Essential Corrosion Software Applications for Corrosion Engineers, Corrosion Researchers, and Corrosion Technicians in Laboratories and in Fields

WebCorr Corrosion Rate Units Converter: Converting Between All Corrosion Rate Units for All Metals and Alloys

|

|

Corrosion Prediction Software for the Building and Construction Industry

|

Concrete-Compass: Concrete Corrosion Prediction and Modeling

CP-Compass-Concrete: Design Calculations for Cathodic Protection of Reinforced Concrete Structures

CP-Compass-Pipeline: Cathodic Protection Design Calculations, Verification, Assessment and Solutions

Soil-Compass: Soil Corrosion Prediction and Modeling for Metals and Alloys

Seawater-Compass: Seawater Corrosion Prediction for Metals and Alloys

GC-Compass: Galvanic Corrosion Prediction and Materials Compatibility Assessment

CRA-Compass: Corrosion Modeling and Corrosion Prediction for Corrosion Resistant Alloys - the Threshold Temperature and Chloride Concentration for Pitting, Crevice Corrosion, and Stress Corrosion Cracking (SCC)

PCW-Compass: Corrosion Prediction and Modeling in Process Cooling Water Systems

Atmosphere-Compass: Prediction and Modeling of Atmospheric Corrosion of Metals and Alloys

SC-Compass: Stray Current Corrosion and AC Corrosion - Identification, Assessment and Prediction

PipelineCompass: Pipeline Corrosion Modeling, Prediction, Assessment and Solutions

ACE - Apps for Corrosion Engineers: A Collection of Essential Corrosion Software Applications for Corrosion Engineers, Corrosion Researchers, and Corrosion Technicians in Laboratories and in Fields

WebCorr Corrosion Rate Units Converter: Converting Between All Corrosion Rate Units for All Metals and Alloys

|

|

Corrosion Prediction Software for the Coatings and Surface Finishing Industry

|

Atmosphere-Compass: Prediction and Modeling of Atmospheric Corrosion of Metals and Alloys

VPC-Compass: Prediction and Modeling of Internal Corrosion in Vapor Phase in Closed Systems

GC-Compass: Galvanic Corrosion Prediction and Materials Compatibility Assessment

PCW-Compass: Corrosion Prediction and Modeling in Process Cooling Water Systems

CRA-Compass: Corrosion Modeling and Corrosion Prediction for Corrosion Resistant Alloys - the Threshold Temperature and Chloride Concentration for Pitting, Crevice Corrosion, and Stress Corrosion Cracking (SCC)

CP-Compass: Cathodic Protection Design Calculations, Verification, Assessment and Solutions

CUI-Compass: Prediction and Risk Assessment of Corrosion Under Insulation and Fireproofing

EVS-Compass: Extreme Value Statistics in Corrosion Modeling and Corrosion Life Prediction of Structures and Plant Assets

WebCorr Corrosion Rate Units Converter: Converting Between All Corrosion Rate Units for All Metals and Alloys

|

|

Corrosion Prediction Software for the Archaeology, National Heritage, Museums and Arts Industry

|

Shipwreck-Compass: Shipwreck Corrosion Modeling and Corrosion Prediction

Atmosphere-Compass: Prediction and Modeling of Atmospheric Corrosion of Metals and Alloys

GC-Compass: Galvanic Corrosion Prediction and Materials Compatibility Assessment

Soil-Compass: Soil Corrosion Prediction and Modeling for Metals and Alloys

CRA-Compass: Corrosion Modeling and Corrosion Prediction for Corrosion Resistant Alloys - the Threshold Temperature and Chloride Concentration for Pitting, Crevice Corrosion, and Stress Corrosion Cracking (SCC)

VPC-Compass: Prediction and Modeling of Internal Corrosion in Vapor Phase in Closed Systems

EVS-Compass: Extreme Value Statistics in Corrosion Modeling and Corrosion Life Prediction of Structures and Plant Assets

CP-Compass: Cathodic Protection Design Calculations, Verification, Assessment and Solutions

H2Compass: Modeling and Prediction of Low Temperature Hydrogen Damages (Hydrogen Blistering, Hydrogen-Induced Cracking, Hydrogen Embrittlement) and High Temperature Hydrogen Attack (HTHA)

WebCorr Corrosion Rate Units Converter: Converting Between All Corrosion Rate Units for All Metals and Alloys

|

|

Corrosion Prediction Software for the General Industry

|

Atmosphere-Compass: Prediction and Modeling of Atmospheric Corrosion of Metals and Alloys

Soil-Compass: Soil Corrosion Prediction and Modeling for Metals and Alloys

ANC-Compass: Modeling and Prediction of Ant Nest Corrosion (Formicary Corrosion) in Copper Tubes

Seawater-Compass: Seawater Corrosion Prediction for Metals and Alloys

Concrete-Compass: Concrete Corrosion Prediction and Modeling

GC-Compass: Galvanic Corrosion Prediction and Materials Compatibility Assessment

CRA-Compass: Corrosion Modeling and Corrosion Prediction for Corrosion Resistant Alloys - the Threshold Temperature and Chloride Concentration for Pitting, Crevice Corrosion, and Stress Corrosion Cracking (SCC)

PCW-Compass: Corrosion Prediction and Modeling in Process Cooling Water Systems

VPC-Compass: Prediction and Modeling of Internal Corrosion in Vapor Phase in Closed Systems

EVS-Compass: Extreme Value Statistics in Corrosion Modeling and Corrosion Life Prediction of Structures and Plant Assets

CP-Compass: Cathodic Protection Design Calculations, Verification, Assessment and Solution

CUI-Compass: Prediction and Risk Assessment of Corrosion Under Insulation and Fireproofing

PipelineCompass: Pipeline Corrosion Modeling, Prediction, Assessment and Solutions

O2Compass: Modeling and Prediction of High Temperature Oxidation

Dew-Point-Compass: Prediction of Dew Point Temperatures of Flue Gases and the Risk of Dew Point Corrosion

SC-Compass: Stray Current Corrosion and AC Corrosion - Identification, Assessment and Prediction

CO2Compass: Modeling and Prediction of Corrosion by Carbon Dioxide (CO2), Hydrogen Sulfide (H2S), Acetic Acid (HAc), Elemental Sulfur (S), and Mercury (Hg) in Oil and Gas Pipelines and Production Tubing.

ACE - Apps for Corrosion Engineers: A Collection of Essential Corrosion Software Applications for Corrosion Engineers, Corrosion Researchers, and Corrosion Technicians in Laboratories and in Fields

WebCorr Corrosion Rate Units Converter: Converting Between All Corrosion Rate Units for All Metals and Alloys |

|

Alphabetical List of All Corrosion Prediction and Corrosion Modeling Software

- Protecting people, assets, and the environment from the

harmful effect of corrosion

-

ABC-Compass: Ammonium Bisulfide Corrosion Modeling and Life Prediction

-

ACE - Apps for Corrosion Engineers: A Collection of Essential Corrosion Software Applications for Corrosion Engineers, Corrosion Researchers, and Corrosion Technicians in Laboratories and in Fields

-

ACMF-Compass: Modeling and Prediction of the Effects of AC and Magnetic Field on Metal Corrosion

-

ANC-Compass: Modeling and Prediction of Ant Nest Corrosion (Formicary Corrosion) in Copper Tubes

-

Atmosphere-Compass: Prediction and Modeling of Atmospheric Corrosion of Metals and Alloys

-

CCC-Compass: Modeling and Prediction of Caustic Corrosion and Caustic Stress Corrosion Cracking

-

CIPAL-Compass: Copper-Induced Pitting in Aluminium Alloys - Modeling, Life Prediction and Process Control

-

Cl2Compass: Modeling and Prediction of Corrosion by Dry Chlorine Gas

-

CO2Compass: Modeling and Prediction of Corrosion by Carbon Dioxide (CO2), Hydrogen Sulfide (H2S), Acetic Acid (HAc), Elemental Sulfur (S), and Mercury (Hg) in Oil and Gas Pipelines and Production Tubing

-

Concrete-Compass: Concrete Corrosion Prediction and Modeling

-

CP-Compass-Pipeline: Cathodic Protection Design Calculations, Verification, Assessment and Solution for Underground Pipelines

-

CP-Compass-Concrete: Design Calculations for Cathodic Protection of Reinforced Concrete Structures

-

CRA-Compass: Corrosion Modeling and Corrosion Prediction for Corrosion Resistant Alloys - the Threshold Temperature and Chloride Concentration for Pitting, Crevice Corrosion, and Stress Corrosion Cracking (SCC)

-

CSR-Compass: Modeling and Remaining Life Prediction of Creep and Stress Rupture of Boiler and Heater Tubes

-

CUI-Compass: Prediction and Risk Assessment of Corrosion Under Insulation and Fireproofing

-

Dew-Point-Compass: Prediction of Dew Point Temperatures of Flue Gases and the Risk of Dew Point Corrosion

-

DWD-Compass: Modeling and Life Prediction of Corrosion in Drinking Water Distribution Systems

-

EN-Compass: Modeling and Prediction of the Corrosion Resistant Properties of Electroless Nickel Coatings

-

EVS-Compass: Extreme Value Statistics in Corrosion Modeling and Corrosion Life Prediction of Structures and Plant Assets

-

F2Compass: Modeling and Prediction of Corrosion by Dry Fluorine Gas

-

FAC-Compass: Erosion Corrosion and Flow - Accelerated Corrosion Modeling, Life Prediction and Materials Selection in Water-Steam Systems

-

FuelAsh-Compass: Fuel Ash Corrosion Modeling and Life Prediction of Boiler and Heater Tubes

-

GC-Compass: Galvanic Corrosion Prediction and Materials Compatibility Assessment

-

H2Compass: Modeling and Prediction of Low Temperature Hydrogen Damages (Hydrogen Blistering, Hydrogen-Induced Cracking, Hydrogen Embrittlement) and High Temperature Hydrogen Attack (HTHA)

-

H2O-Compass: Modeling and Prediction of Water Corrosivity and Scaling Tendency

-

H2SO4-Compass: Corrosion Prediction and Materials Selection Guide for Sulphuric Acid (H2SO4) Services

-

HBr-Compass: Corrosion Prediction and Materials Selection Guide for Hydrobromic Acid (HBr) Services

-

HCl-Compass: Corrosion Prediction and Materials Selection Guide for Hydrochloric Acid (HCl) Services

-

HF-Compass: Corrosion Prediction and Materials Selection Guide for Hydrofluoric Acid (HF) Services

-

ISO15156-Compass: Modeling and Prediction of in-situ pH, Region of Environmental Severity, and Susceptibility to Sulfide Stress Cracking (SSC) of Carbon and Low Alloy Steels

-

MIC-Compass: Modeling and Prediction of Microbiologically Influenced Corrosion in Oil and Gas Pipelines

-

MSC

-Compass: Modeling and Prediction of Corrosion in Molten Salts for TES and MSR Applications

-

NAC-Compass: Modeling and Prediction of High Temperature Naphthenic Acid Corrosion

-

NH3Compass: Modeling and Prediction of Corrosion in Ammonia Production, Storage, and Transport

-

O2Compass: Modeling and Prediction of High Temperature Oxidation

-

OCTG-Compass: Corrosion Prediction and CRA Materials Selection Guide for Oil and Gas Production Systems

-

PCW-Compass: Corrosion Prediction and Modeling in Process Cooling Water Systems

-

PipelineCompass: Pipeline Corrosion Modeling, Prediction, Assessment and Solutions

-

S-Compass: Modeling and Prediction of High Temperature Sulfidation/Sulfidic Corrosion/H2-H2S Corrosion and Low Temperature Elemental Sulfur Corrosion

-

SC-Compass: Stray Current Corrosion and AC Corrosion - Identification, Assessment and Prediction

-

Seawater-Compass: Seawater Corrosion Prediction for Metals and Alloys

-

Shipwreck-Compass: Shipwreck Corrosion Modeling and Corrosion Prediction

-

Soil-Compass: Soil Corrosion Prediction and Modeling for Metals and Alloys

-

SPE-Compass: Solid Particle Erosion Modeling and Prediction

-

VPC-Compass: Prediction and Modeling of Internal Corrosion in Vapor Phase in Closed Systems

-

VPC-Compass-SE: Prediction and Modeling of Corrosion in Microelectronic Packages

-

WebCorr Corrosion Rate Units Converter: Converting Between All Corrosion Rate Units for All Metals and Alloys

Each and every one of WebCorr's corrosion prediction and modeling software was developed at the request of our clients worldwide. Our clients' inputs and specific requirements help make our corrosion software always stay relevant, practical, and directly applicable to the various systems, processes and industries. If you cannot find a corrosion prediction software of your interest from the list above, please let us know and we will work with you to customize an existing software or develop a new one to meet your specific requirements.

Alternatively, we can run the appropriate corrosion prediction

software for you as a service using the data you provide to us.

Request for Licensing Details

|

Why You Should Consider WebCorr WebCorr was founded in

1995 and has been a leader in corrosion prediction and modeling software

development. WebCorr has developed 47 integrated predictive software

programs for corrosion prediction and modeling, cementing a CorrCompass-based

ecosystem encompassing different types of corrosion in every industry

and service environment. Extensive field data from our corrosion consulting work help keep the predictive engines in our corrosion software always accurate

and up-to-date with applicable codes, standards, and best industry

practices. Unlike other corrosion prediction software and corrosion modeling software developed by computer programmers, mechanical engineers, metallurgists or chemists, WebCorr's corrosion prediction software and corrosion modeling software are developed by NACE certified Corrosion Specialists with both BEng and PhD degrees in corrosion and decades of practical corrosion experience. The WebCorr team knows corrosion from inside out.

Our confidence in the accuracy of WebCorr's corrosion prediction and

modeling software is backed by our performance guarantee.

Performance Guarantee

WebCorr is the only corrosion software developer who offers performance guarantee. If at any time during the licensing period, the corrosion rates predicted by WebCorr's

corrosion prediction software and corrosion modeling software are not

closer to the measured values than the values predicted by any other

corrosion prediction and corrosion modeling software on the market, we

will refund the pro-rated licensing fee to you.

Unparalleled Functionality WebCorr's corrosion prediction software and corrosion modeling software utilize machine learning and cloud computing to optimize the predictive engines such that all contributing factors to the corrosion process are accurately processed. The prediction and modeling results are validated against field data and lab data. Take CO2 corrosion modeling as an example, traditional CO2 corrosion modeling software is limited in their capability to the prediction of the corrosion rate only, without due consideration to the CO2 corrosion control strategy under the prevailing operating conditions of a pipeline or production tubing. WebCorr's CO2Compass, the next generation of CO2 corrosion modeling software goes far beyond the prediction of the corrosion rate, it utilizes machine learning and cloud computing to optimize a particular CO2 corrosion control strategy with specific and quantitative control targets under the prevailing operating conditions of a pipeline or production tubing. Significant cost savings can be realized for asset owners at both the design and operation phases of pipelines. CO2Compass is not just for CO2 corrosion rate prediction, it also provides users with expert guidance on practical solutions for mitigating CO2 corrosion. Based on the predicted corrosion rate, the prevailing operating conditions, the flow regimes, and the water analysis results, CO2Compass makes an overall assessment of the complete system and generates recommendations for CO2 corrosion mitigation strategies.

Click here to read more on CO2Compass, the next generation of CO2 corrosion prediction and CO2 corrosion modeling software.

Unmatched Usability WebCorr' CorrCompass suites of corrosion software are designed with end users in mind. Experience the industry's first cross-platform and device-independent corrosion modeling and corrosion prediction applications on your iPads, tablets, smart phones, notebooks and desktops, at any time and anywhere, in the office or in the field. No installation files to download, no browser plug-ins required, no USB dongles to carry around, and no license keys to transfer from one PC to another. WebCorr's Compass series of software simply works on any device running any OS. All you need is an internet browser. The predictive engines in the Compass software perform calculations in the cloud, with real-time display of prediction results and graphical charts. Unlike the black-box style of other corrosion modeling software, WebCorr's Compass series of corrosion software gives the user complete and direct control over the modeling of the effects of all parameters contributing to corrosion. Take CO2 corrosion modeling for example, CO2Compass gives the user complete and direct control over the modeling of the effects of scaling, oil wetting, glycol, CO2 fugacity, in-situ pH, liquid velocity, organic acids, and H2S with user-controlled ON/OFF switches, and direct inputs overriding the default settings. No other CO2 corrosion modeling software gives you all of these controls. Automatically generated and dynamically updated graphs are plotted in real-time as the user makes adjustments to the input parameters. These plots include corrosion rate profile, effect of temperature, effect of velocity, and effect of pH on the predicted CO2 corrosion rates. Saturation indices of carbonates and sulphate scales are also plotted. A clean and concise report is automatically generated and dynamically updated in real-time as you enter or change the input parameters.

Click here to read more on CO2Compass, the next generation of CO2 corrosion prediction and CO2 corrosion modeling software.

Any Device Any OS WebCorr's Compass series of corrosion software simply works on any device running any OS. All you need is an internet browser. You can run the corrosion prediction and corrosion modeling software on your tablets, notebooks and desktops, at any time and anywhere, in the office or in the field. There are no installation files to download and install, no browser plugins required, no USB dongles to carry around, and no license keys to transfer from one PC to another. Just login with your username and password, enter your data and print out the report.

Free Training and Technical Support Your initial 1‐year license comes with free training in our Singapore office for 2 persons from your company. Fees for additional persons or on-site training at your company will be quoted on request.

Unlike other corrosion prediction software developer who charges maintenance support fees, WebCorr Corrosion Consulting Services provides free technical support to our customers. Our Compass series of software utilizes cloud computing and every time when you login to the software portal, you are using the most up-to-date version. There is no need for end users to download or apply any update.

WebCorr provides comprehensive corrosion consulting, corrosion training and corrosion expert witness services across the globe. If required, WebCorr can carry out the corrosion modeling, corrosion prediction, corrosion simulation, review and validation of reports/designs/calculations for your company, at a fee to be quoted on request.

WebCorr has provided the following corrosion prediction and corrosion modeling services for our clients:

-

CO2 Corrosion prediction and CO2 corrosion modeling in oil and gas pipelines and production tubing.

-

H2S Corrosion prediction and H2S corrosion modeling in oil and gas pipelines and production tubing.

-

Corrosion prediction and corrosion modeling of

bottom of line corrosion (BOL or BLC) in multiphase flow pipelines.

-

Corrosion prediction and corrosion modeling of top of line corrosion (TOL or TLC) in multiphase flow pipelines.

-

Corrosion prediction and corrosion modeling of internal pitting corrosion in pipelines.

-

Corrosion prediction and corrosion modeling of external pitting corrosion of buried pipelines.

-

Corrosion prediction and corrosion modeling of the effects of chemical treatment and corrosion inhibitors on the corrosion rate of specific alloys.

-

Corrosion prediction and corrosion modeling of corrosion in chemical process and pharmaceutical industries

-

Corrosion prediction and corrosion modeling of the effects of process pressure, velocity (flow rate) and temperature (PVT) on the corrosion rate of steels and alloys.

-

Independent 3rd party verification/validation of modeled/predicted corrosion growth rates. At WebCorr, our NACE certified Corrosion Specialist will validate your modeled/predicted corrosion growth rates using properly selected models, laboratory test results and field data in the literature. Our verification/validation report will come complete with all supporting data and reference documents. If necessary, we can train your engineers on CO2 corrosion modeling. Click the link below to see details on our 5-day training course on CO2 corrosion modeling:

CO2 Corrosion Modeling for the Prediction of Internal Corrosion in Oil Gas Pipelines and Production Tubing.

-

CO2 Corrosion Model Validation Matrix and CO2 Corrosion Model Validation Index Score (CO2MoVIS).

-

Remaining life prediction of a shipwreck.

-

Life prediction of a silo storage system for nuclear waste storage and

disposal.

-

Materials selection for an ammonia production plant.

-

Modeling LiF Corrosion of carbon steel in boiling water.

-

Assessment of the risk of stress corrosion cracking of carbon steel in

LiOH and NaOH solutions

In the case illustrated below, corrosion modeling is the only solution to establish the safe operation limits (temperature, concentrations of impurities) for the tanks carrying phosphoric acid.

|